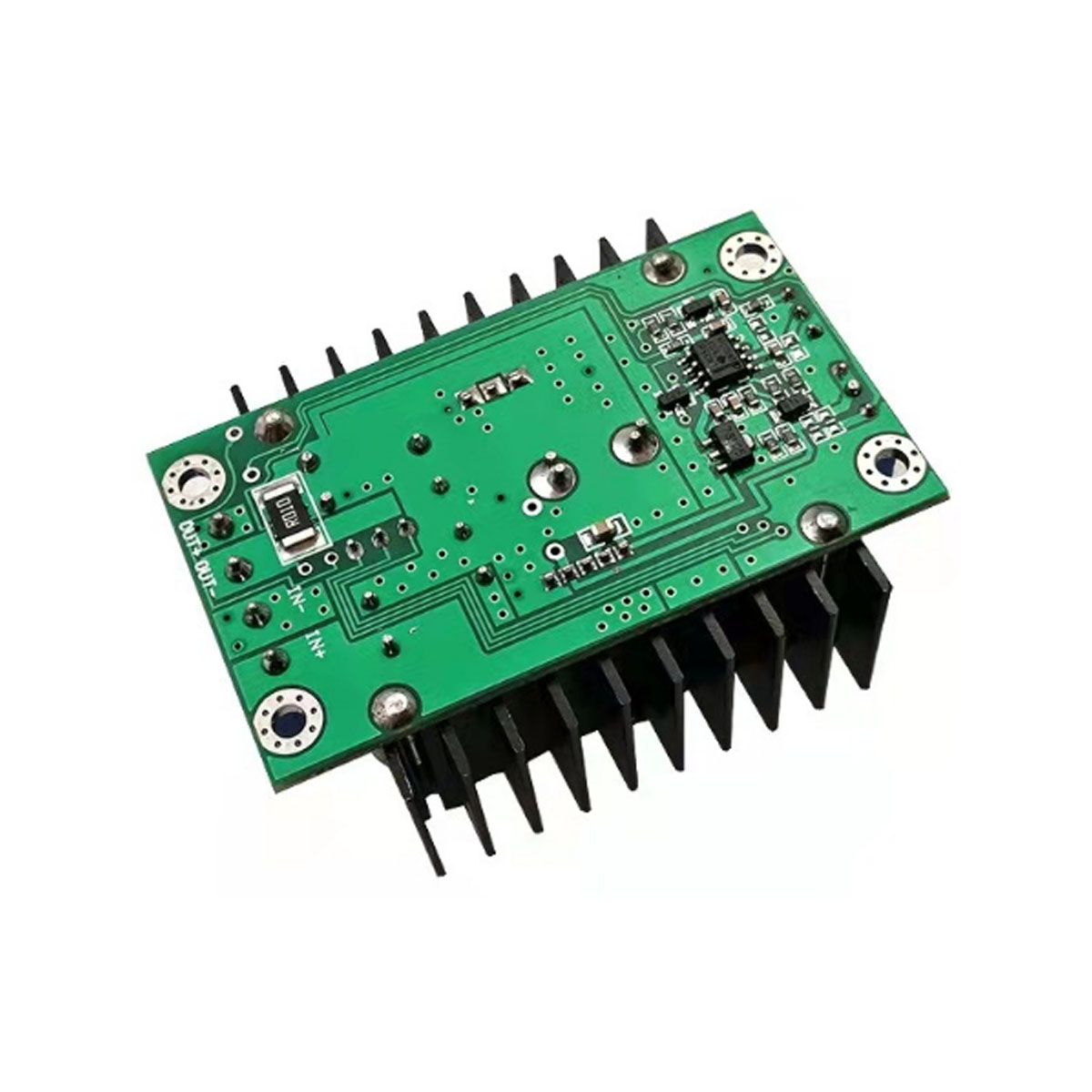

Dc-dc 9A buck down module 300W power module

DC-DC 9A step-down module 300W power module 12A step-down constant voltage constant current adjustable voltage converter.

Additional information

| SKU | GA003 |

|---|---|

| MOQ | 1 |

| Availability | In stock |

Product Details:

Tips:

(Stock: the maximum current is 8-9A, the highest input voltage is 40V output voltage is about 35V)

(Because the 12A current chip manufacturer stopped production, the current of the replacement chip was reduced from 12A to 8A (the actual maximum current was around 9A), the input voltage was increased from 32V to 40V, and the output voltage was increased from 28V to 35V. It can supply power for 10 strings of high-power LED. Further notice will be given when 12A chips arrive.)

Dimensions: 65(l)*47(W)*23.5(H) mm

Typical applications:

Adjustable power supply (12A power is large enough), high-power LED drive, LED display drive, lead battery charging, lithium battery charging, vehicle power supply, vehicle notebook power supply (step-down), voltage regulator power supply, low-voltage system power supply, (such as children’s toy car 12V battery step-down to 6V), 24V to 12V 12A \\\\12V to 5V 12A \\\\24V to 5V 12A \\\\24V to 19V20V and so on, the application range is very wide.

1. Fixed lamp current is 0.1 times of the constant current value (used to identify whether the battery is full when charging);

2. Special reference IC and high-precision sampling resistor are used to make the constant current more stable (temperature drift is less than 5% when 20 degrees to 60 degrees constant current 5A). Especially suitable for LED drivers

3. Large output current, the maximum output current can reach 12A, to meet most needs.

4. 4 high frequency capacitor, effectively reduce output ripple, improve working stability

5. Double heat sink design, MOS tube Schottky diode independent heat sink, good heat dissipation, mutual influence

6. Use large size iron, silicon and aluminum magnetic ring at all costs to improve work efficiency, and use pure copper double wire to reduce heat and improve efficiency.

7. 3296 multi-turn potentiometer, high voltage and current regulation precision, good stability.

8. Special current sampling resistance high current sampling accuracy, good stability, small temperature drift. Leds necessary.

9. Dual-color indicator light, clear working status. A must for charging.

10. Voltage and current are adjustable, adjustable power supply effect is good, 12A current is large, power is sufficient.

Module parameters:

1. Nature of the module:Non-isolated step-down constant current, constant voltage module (CC CV) charging module

2. Scope of application: high power LED constant current drive, lithium battery charging (including ferroelectric),4V, 6V, 12V, 14V, 24V battery charging, nickel cadmium nickel-metal hydride battery (battery pack) charging, solar panel, wind generator

3. Input voltage: 7-32V(without constant current 5-32V)

4. Output voltage :

(1) continuously adjustable (0.8-28v)

(2) Fixed output (choose between 0.8-28V), please tell the shopkeeper when buying. (Only for batch customers for the time being, all samples will be sent to adjustable type)

(3) If you need higher voltage, please contact me directly

5. Output current: maximum 12A (if the power tube temperature exceeds 65 degrees, please add fan for cooling, 24V to 12V within 6A open environment generally can not add fan)

6. Constant current range: 0.2-12A (adjustable) (without constant current without this function)

7. Lamp current: constant current value * (0.1), lamp current and constant current value linkage, such as constant current value 3A, lamp current is set to 0.1 times of constant current (0.1*3A= 0.3a), when the constant current value is adjusted to 2A, the lamp current is 0.1 times of constant current (0.1*2A= 0.2a).

The secondary version is fixed at 0.1 times (the actual lamp current is approximate value is not very accurate) for charging whether full indication.

8. Lowest pressure difference: 1V

9. Output power: the maximum power is about 300W. If the temperature of the power tube exceeds 65 degrees, add a fan.

10. Conversion efficiency: up to 95% (the higher the output voltage, the higher the efficiency)

11. Operating frequency: 300KHZ

12. Output ripple: 20M bandwidth (for reference only)

Input 24V output 12V 5A Ripple 50mV (excluding noise)

13. Working temperature: industrial grade (-40℃ to +85℃) (please pay attention to the power tube temperature in actual use, please strengthen the heat dissipation if the temperature is too high)

14. No-load current: typical 20mA(24V to 12V)

15. Load adjustment rate: ±1% (constant voltage)

16. Voltage adjustment rate: ±1%

17. Constant current accuracy and temperature: in the actual test, the temperature on the module changed from 25 degrees to 60 degrees, and the constant current value changed less than 5% (constant current value 5A)

18. Dynamic response speed: 5% 200uS

19. Potentiometer adjustment direction: clockwise (increase), counterclockwise (decrease) near the input potentiometer for voltage regulation (CV), near the output potentiometer for current regulation (CC)

20. Indicator light: two-color indicator light, charging indicator light red, charging indicator light green (not connected to the load green) without constant current indicator light red.

21. Output short-circuit protection: yes, constant current (currently set constant current value)

22. Input reverse connection protection: None,

23. Output to prevent countercurrent: none.

24. Wiring mode: wiring terminal

Usage of battery charging:

1. Determine the floating charging voltage and charging current of the battery you need to charge, and the input voltage of the module;

2. Adjust the constant voltage potentiometer to adjust the output voltage to about 5V.

3. Use multimeter 10A current block to measure the output short-circuit current, and adjust the constant-current potentiometer to make the output current reach the predetermined charging current value;

4. Adjust the constant-voltage potentiometer to make the output voltage reach the floating charging voltage;

5. Connect the battery and charge it.

(Step 1, 2, 3 and 4 connect the input power to the module, and no battery to the output when no load.)

LED constant current driver usage:

1. Determine the operating current and maximum operating voltage that you need to drive the LED;

2. Adjust the constant voltage potentiometer to adjust the output voltage to about 5V.

3. Use multimeter 10A current block to measure the output short-circuit current, and adjust the constant-current potentiometer to make the output current reach the predetermined LED working current;

4. Adjust the constant-voltage potentiometer to make the output voltage reach the highest working voltage of LED;

5. Connect LED, test machine.

(Step 1, step 2, step 3 and step 4 connect the input power of the module to the power supply, and no LED light is connected to the output when no load.)